- NEW

PNEUMATIC ROLLER LIFTING TABLE ST-3 HDK ROL 3000 - Bestseller

_300_300_c.jpg)

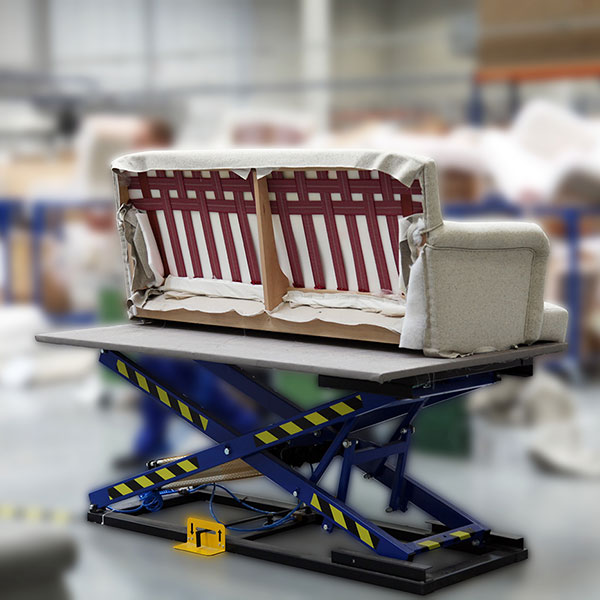

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3 -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/B -

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/BR - Bestseller

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/K -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/KP -

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/KPO -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/R -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/RB -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/KRB -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/HD -

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/HDKRB -

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/HDKRBC -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/ROL MINI -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3 MINI OP -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/O -

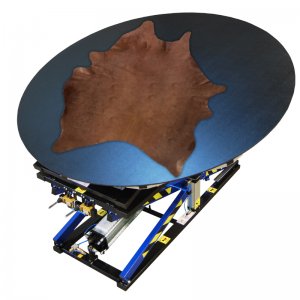

PNEUMATIC LIFTING TURNTABLE FOR LEATHER ST-3/OS -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3 MINI -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/R MINI -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-3/PE MINI -

PNEUMATIC LIFTING TABLE FOR SOFA PACKAGING ST-3/O/C -

FOIL UNWINDING AND CUTTING TABLE K2-0597 -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-2/OK -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR GLUING ST-4 - Bestseller

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR GLUING ST-4/B -

_300_300_c.jpg)

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-5 -

PNEUMATIC LIFTING TABLE FOR SOFA PACKAGING ST-6 -

PNEUMATIC LIFTING TABLE FOR UPHOLSTERY ST-7 KRB B -

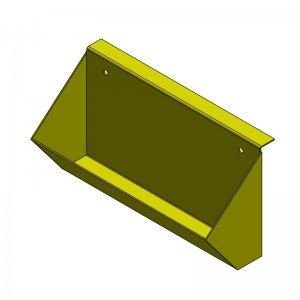

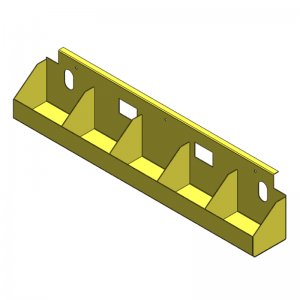

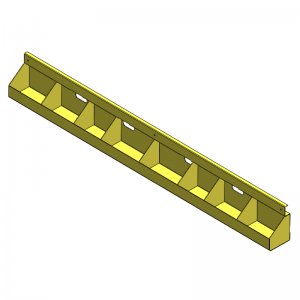

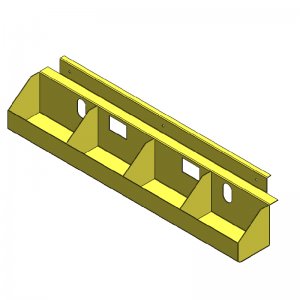

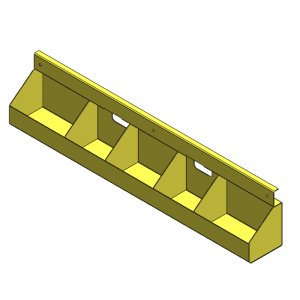

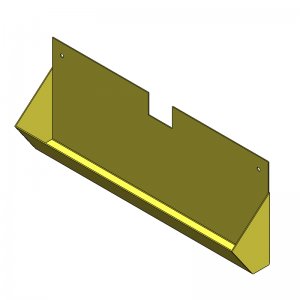

DRAWER DR-1 -

DRAWER DR-2 -

DRAWER DR-3 -

DRAWER DR-4 -

DRAWER DR-5 -

DRAWER DR-6 -

DRAWER DR-7 -

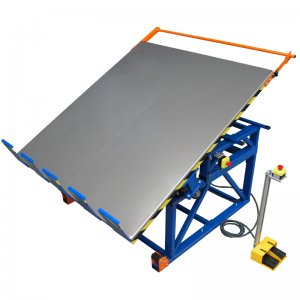

PANEL FLIPPING TABLE SDM-200 -

TILT ABLE PACKAGING AND ASSEMBLY TABLE SOP-1 -

TILT ABLE PACKAGING AND ASSEMBLY TABLE SOP-1 MINI

- Bestseller

_300_300_c.jpg)

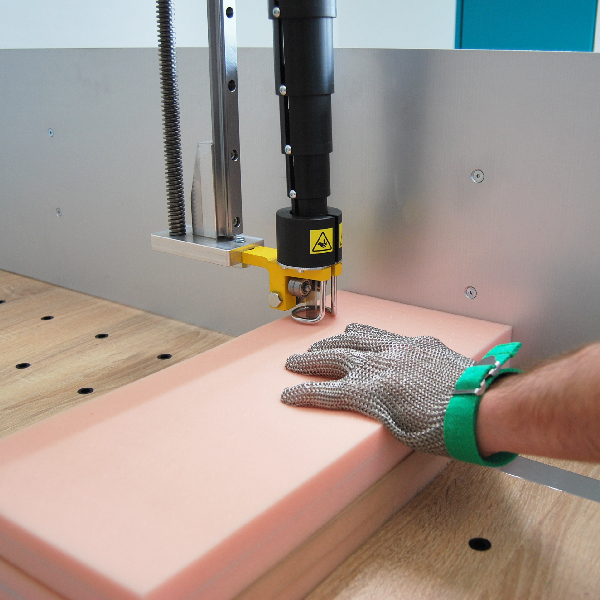

BAND KNIFE MACHINE WITH SLIDING TABLE R1150/PB -

BAND KNIFE MACHINE R1250 - Bestseller

BAND KNIFE MACHINE FOR UPHOLSTERY FOAM R1150 - Bestseller

BAND KNIFE MACHINE R1000 -

BAND KNIFE MACHINE WITH SLIDING TABLE R1000/PB -

BAND KNIFE MACHINE R750 -

_300_300_c.jpg)

BAND KNIFE MACHINE R500/F -

_300_300_c.jpg)

BAND KNIFE MACHINE R500 -

MANUAL MEASURING DEVICE FOR BAND KNIFE PR-3_1S -

_300_300_c.jpg)

MANUAL MEASURING DEVICE FOR BAND KNIFE PR-3 -

MANUAL MEASURING DEVICE FOR BAND KNIFE PR-3/A -

MANUAL MEASURING DEVICE FOR BAND KNIFE PR-3/EP -

_300_300_c.jpg)

BAND KNIFE MACHINE VACUUM CLEANING SYSTEM PS-220

- NEW

FABRIC REWINDING MACHINE P-4SE -

FABRIC REWINDING MACHINE P-3L - Bestseller

_300_300_c.jpg)

FABRIC REWINDING MACHINE P-3S -

FABRIC REWINDING-INSPECTION MACHINE PP-3L - Bestseller

_300_300_c.jpg)

FABRIC REWINDING-INSPECTION MACHINE PP-3S -

FABRIC REWINDING-INSPECTION MACHINE PP-3SE -

UNIVERSAL FABRIC INSPECTION MACHINE PP-5 -

UNIVERSAL FABRIC INSPECTION MACHINE PP-5/AE -

_300_300_c.jpg)

FABRIC REWINDING AND CUT-TO-LENGTH MACHINE CTLR-1500 -

_300_300_c.jpg)

FABRIC REWINDING AND CUT-TO-LENGTH MACHINE CTLR-2000 -

FABRIC REWINDING, INSPECTION AND CUT-TO-LENGTH MACHINE CTLR-2000-K3-0028 -

FABRIC REWINDING AND CUT-TO-LENGTH MACHINE CTLR-2000 KC -

ROLLER BLINDS FABRIC REWINDING AND CUT-TO-LENGTH MACHINE CTLR-3200 ECO -

FABRIC INSPECTION AND CUT-TO-LENGTH MACHINE FOR BLINDS FABRIC CTLR-3000 -

FABRIC REWINDING AND INSPECTION MACHINE CTLR-3300 -

FABRIC WINDING MACHINE NT-1/L -

CRADLE WITH COUNTER KZL-1 FOR NT-1/L

- NEW

PNEUMATIC PRESS WITH DRAWSTRING SYSTEM PDNS-2 -

_300_300_c.jpg)

PNEUMATIC PRESS FOR UPHOLSTERED SEATS PDP-1 - Bestseller

_300_300_c.jpg)

PNEUMATIC PRESS FOR UPHOLSTERED SEATS PDK-1 -

PNEUMATIC PRESS WITH DRAWSTRING SYSTEM PDK-2/PDS -

_300_300_c.jpg)

PNEUMATIC PRESS FOR UPHOLSTERY PDM-1 MINI -

_300_300_c.jpg)

PNEUMATIC PRESS FOR UPHOLSTERY PDM-1 -

_300_300_c.jpg)

PNEUMATIC PRESS FOR UPHOLSTERY PDM-1/HD -

PNEUMATIC PRESS FOR UPHOLSTERY PDM-1M-D -

PNEUMATIC PRESS FOR UPHOLSTERY PDM-3B -

_300_300_c.jpg)

ASSEMBLING UNIT FOR ZIG-ZAG SPRINGS NS-1 -

_300_300_c.jpg)

ASSEMBLING UNIT FOR ZIG-ZAG SPRINGS NS-3

- NEW

MATTRESS COVER SEWING TABLE WITH AIR CUSHION SK-3 AIRSEW -

FABRIC CUTTING MACHINE NTH-100 - Bestseller

FABRIC CUTTING MACHINE NTH-125 - Bestseller

_300_300_c.jpg)

CUTTING ROOM TABLE SK-3 -

SWIVEL CUTTING ROOM TABLE SK-3/O -

_300_300_c.jpg)

AIR-BLOW CUTTING TABLE SK-3/AIR -

AIR-BLOW AND VACUUM CUTTING TABLE SK-3/AIRVAC - Bestseller

_300_300_c.jpg)

MANUAL FABRIC SPREADING MACHINE UL-3 -

_300_300_c.jpg)

FABRIC SPREADING MACHINE WITH AIR-BLOWING UL-3/AIR -

ROLLER TABLE SK-3/ROL -

_300_300_c.jpg)

FABRIC CLAMP LD-2 -

SEMI-AUTOMATIC FABRIC END-CUTTER OT-1/A -

MANUAL FABRIC END-CUTTER OT-1/R -

MANUAL FABRIC END CUTTER FOR THICK MATERIALS OT-1/RH -

HEAVY DUTY END-CUTTER UK-1 - Bestseller

_300_300_c.jpg)

ULTRASONIC MANUAL CUTTER FOR TEXTILES TTS-400 -

ADJUSTABLE WORKSTATION HDP-1 -

AUXILIARY TABLE FOR CUTTING ROOMS SK-1 -

_300_300_c.jpg)

MATERIAL ROLL RACK LS-1 -

MATERIAL ROLL RACK LS-1/B -

_300_300_c.jpg)

MATERIAL ROLL RACK LS-1/W -

_300_300_c.jpg)

MATERIAL ROLL RACK LS-1/K -

_300_300_c.jpg)

MATERIAL ROLL RACK LS-3 -

_300_300_c.jpg)

MATERIAL ROLL RACK LS-5 -

_300_300_c.jpg)

MATERIAL ROLL RACK LS-6 -

HEAVY-DUTY MATERIAL ROLL RACK LS-6/HD -

MATERIAL ROLL RACK LS-8 -

WALL MOUNTED HEAVY-DUTY MATERIAL ROLL RACK LS-1/PC

- NEW

VERTICAL TULLE CUTTING MACHINE TL-1M - NEW

MOTORIZED REWINDING TABLE FOR ROLLER BLIND FABRICS PMR-2 -

MANUAL MEASURING STOPS PR-11 -

CUTTING TABLE FOR ROLLER BLINDS UK-4 -

CUTTING TABLE FOR ROLLER BLINDS US-2 - Bestseller

CUTTING TABLE FOR ROLLER BLINDS US-1 - Bestseller

CUTTING TABLE FOR ROLLER BLINDS UK-2 -

_300_300_c.jpg)

CUTTING TABLE FOR ROLLER BLINDS UK-1 MAX -

CUTTING TABLE FOR ROLLER BLINDS UK-2 ECO -

_300_300_c.jpg)

ULTRASONIC KNIFE UPGRADE SET FOR UK-2 ECO -

ROLLER BLIND FABRIC WINDING UNIT ZT-1 -

_300_300_c.jpg)

ROLLER BLINDS CONTROL LIFT WK-1 -

INSPECTION HOIST WK-1/HD -

INSPECTION HOIST WK-2/HD - NEW

VERTICAL CURTAIN CUTTING MACHINE UCF-2 -

HOLDERS FOR INSPECTION HOIST -

MANUAL LENGTH MEASURING STOP WITH TABLE PR-1/S -

MEASURING BAR SUW-2 - Bestseller

_300_300_c.jpg)

ULTRASONIC MANUAL CUTTER FOR TEXTILES TTS-400 -

AUTOMATIC MEASURING STOP PA-1 -

AUTOMATIC MEASURING STOP PA-2 -

MANUAL REWINDING TABLE FOR ROLLER BLINDS FABRICS PMR-1 -

ROLLER BLINDS FABRIC REWINDING AND CUT-TO-LENGTH MACHINE CTLR-3200 ECO -

FABRIC INSPECTION AND CUT-TO-LENGTH MACHINE FOR BLINDS FABRIC CTLR-3000 -

ROLLER BLINDS FABRIC INSPECTION TABLE SP-1/ER -

ASSEMBLY CONVEYOR LMK-1

- Bestseller

_300_300_c.jpg)

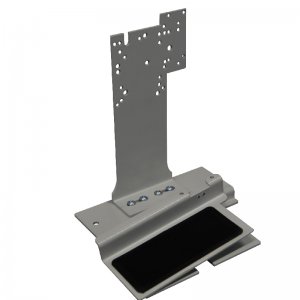

INDUSTRIAL SEWING MACHINE STAND REX-1 -

_300_300_c.jpg)

INDUSTRIAL SEWING MACHINE STAND REX-2 - Bestseller

INDUSTRIAL SEWING MACHINE STAND REX-1HD -

INDUSTRIAL SEWING MACHINE STAND REX-2HD -

INDUSTRIAL SEWING MACHINE STAND REX-3 -

INDUSTRIAL SEWING MACHINE STAND REX-4S -

INDUSTRIAL SEWING MACHINE STAND REX-4K -

INDUSTRIAL FEED OFF THE ARM STAND REX-5S -

INDUSTRIAL FEED OFF THE ARM STAND REX-5K -

INDUSTRIAL SEWING MACHINE STAND REX-6S -

INDUSTRIAL SEWING MACHINE STAND REX-7S - Bestseller

INDUSTRIAL SEWING MACHINE STAND REX-7K -

INDUSTRIAL SEWING MACHINE STAND REX-7U -

WHEELS UPGRADE FOR REX-7U -

INDUSTRIAL SEWING MACHINE PEDESTAL STAND REX-8 -

INDUSTRIAL SEWING MACHINE STAND REX-9 -

INDUSTRIAL SEWING MACHINE STAND REX-10 -

INDUSTRIAL FEED OFF THE ARM STAND REX-11 - Bestseller

INDUSTRIAL SEWING MACHINE STAND REX-12K -

INDUSTRIAL SEWING MACHINE STAND HDP-1EK-R -

INDUSTRIAL SEWING MACHINE STAND (MANUAL standard) HDP-1MS -

INDUSTRIAL SEWING MACHINE STAND (MANUAL wheels) HDP-1MK - Bestseller

INDUSTRIAL SEWING MACHINE STAND (ELECTRIC standard) HDP-1ES - Bestseller

INDUSTRIAL SEWING MACHINE STAND (ELECTRIC wheels) HDP-1EK -

TREADLE ROD FOR INDUSTRIAL SEWING MACHINE CS-1 -

BIG PEDAL DP-1 -

SMALL PEDAL MP-1 -

PEDAL STP-3 -

PEDAL FOR STANDING OPERATION STP-2 -

PEDAL FOR STANDING OPERATION STP-1 - Bestseller

PLASTIC DRAWER WITH GUIDES SZP-1 -

BRACKET FOR OVERLOCK WASTE CHUTE OV-1 -

UNIVERSAL OVERLOCK EXTENSION PLATE OV-2 -

UNIVERSAL OVERLOCK EXTENSION PLATE OV-3 -

BRACKET FOR OVERLOCK WASTE CHUTE OV-4

- NEW

MATERIAL UNWINDING AND CUT-TO-LENGTH MACHINE CTLR-1500 P -

LEATHER STRIP CUTTING TABLE UCP-1 -

PRECISION FABRIC STRIP CUTTING MACHINE UK-2.VS2400 -

ULTRASONIC CUT-TO-LENGTH MACHINE CTL-2000 UM K3 – 0036 -

ULTRASONIC CUT-TO-LENGTH MACHINE CTL-2000 UM -

CUT-TO-LENGTH MACHINE FOR FILTER MATERIALS CTL-2000 FT -

_300_300_c.jpg)

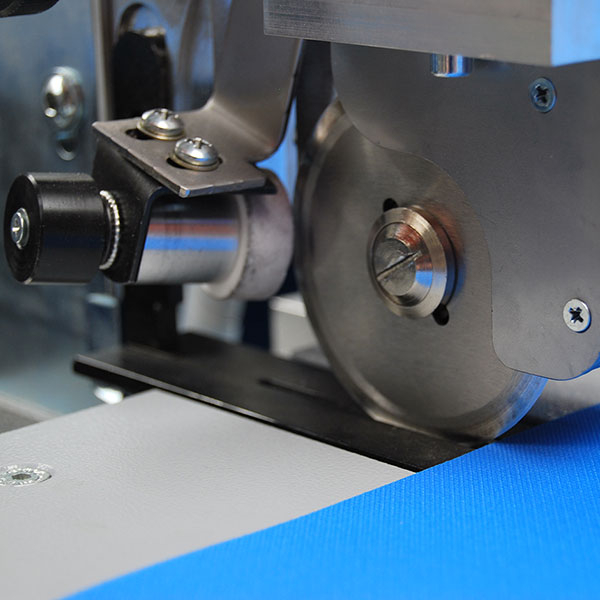

CUT-TO-LENGTH MACHINE FOR PVC COATED FABRIC CTL-2000 -

_300_300_c.jpg)

CUT-TO-LENGTH MACHINE FOR NONWOVEN FABRIC CTL-3000 -

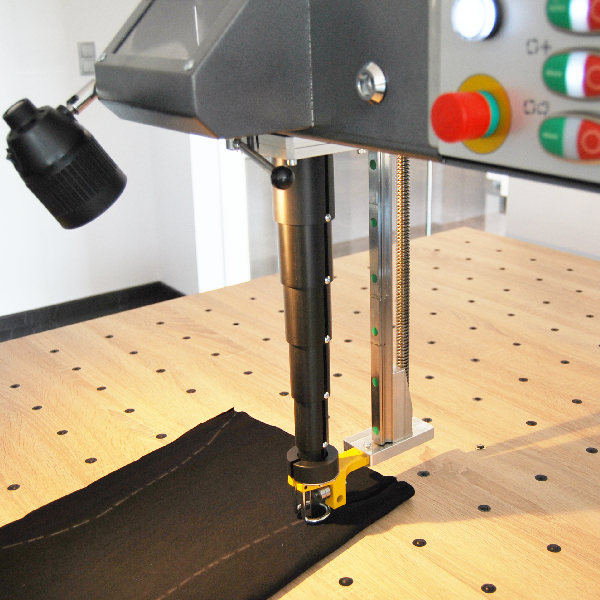

AUTOMATIC CREASING MACHINE K2-0323

_300_300_c.jpg)

_300_300_c.jpg)

_300_300_c.jpg)

_300_300_c.jpg)

_300_300_c.jpg)

_300_300_c.jpg)

_300_300_c.jpg)

_300_300_c.jpg)