In today’s competitive furniture manufacturing industry, efficiency is critical during production. However, out of all upholstery manufacturing stages, packing sofas is quite time-consuming and labour-intensive. It involves lifting, wrapping, turning, and protecting heavy sofa elements with great care, ensuring they reach customers in its best condition. In this article we will dive deep how to improve upholstered furniture packaging process.

The two stand-out pieces of equipment for the sofa packaging process are:

REXEL company manufacturers and supplies both these equipment for a smooth workflow of packaging, easing operators’ work strain, and enhancing efficiency.

Here is a basic process how upholstered furniture is packed:

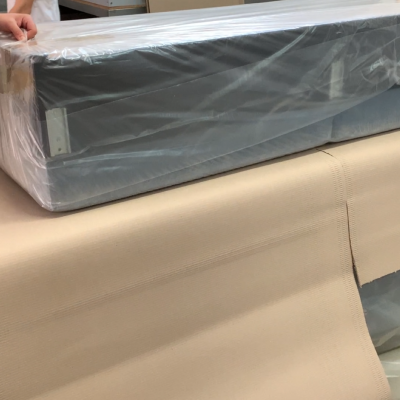

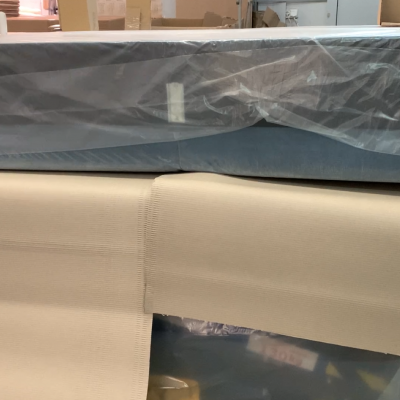

1. Packaging materials are fed from the K2-0597 table. A layer of external packing foil and cardboard sheets is laid onto the ST-3/O/C table.

2. Another layer of clean foil is placed on the tabletop.

3. A sofa element or upholstered furniture component is positioned on the table.

4. Using foot pedals, the operator adjusts the table height for improved working comfort.

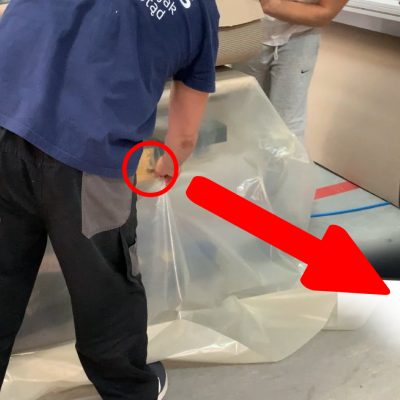

5. The external foil is folded and taped around the sofa.

6. The operator lifts the sofa using the table’s control switch.

7. The central support bar keeps the sofa balanced, allowing the operator to place cardboard edge protectors.

8. After the protectors are fitted, the sofa is lowered using the same control switch described in point (6).

9. A cardboard layer is wrapped around the sofa and fixed with packing tape.

10. The external foil is wrapped again, fixed with packing tape, and all packaging labels are applied.

11. The swivel tabletop is rotated to make it easier to slide the sofa off the ST-3/O/C table.

12. The sofa is placed onto a small wheeled trolley and moved to storage or shipping.

This synchronisation increases accuracy, decreases handling time, and reduces strain on workers. See below photos how the process looks.

The issues with bulky sofa designs are that teams have to struggle a lot during packaging due to their size and weight. Some of the major challenges in this include:

All these challenges cause less productivity while increasing the risk of product damage. This can be an expensive problem for any manufacturer. Therefore, they need advanced ergonomics-driven equipment to make the sofa packaging process smoother.

Also Read: How to increase the efficiency of upholstered furniture production?

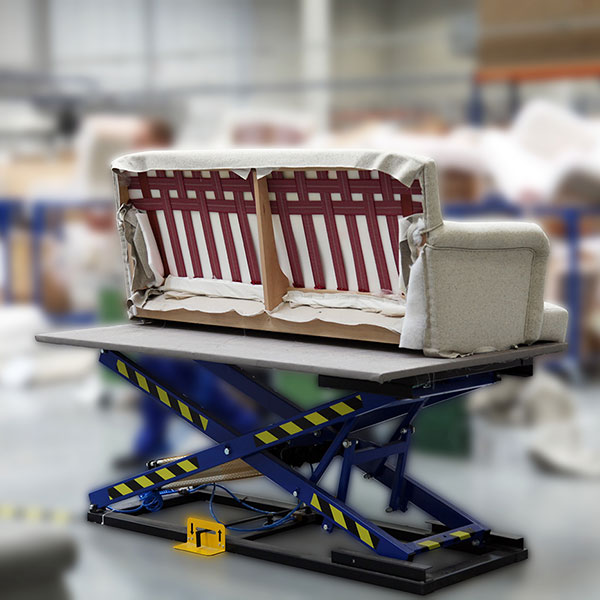

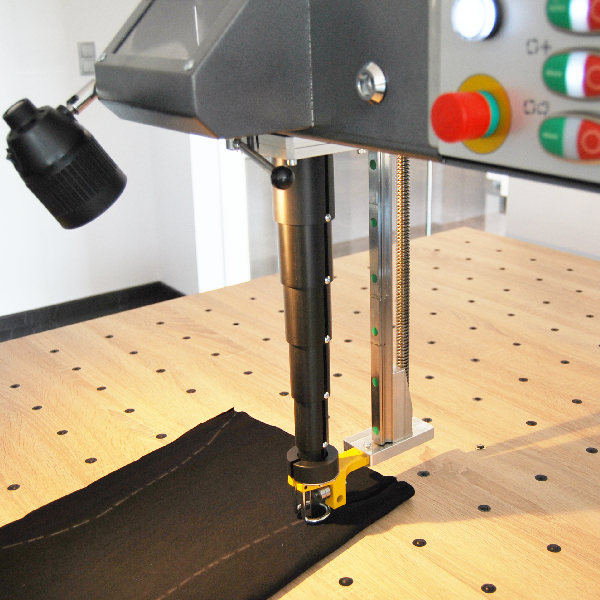

This specific pneumatic lifting table supports heavy upholstery elements at the time of packaging stage. It replaces the conventional trestles with carpet covered, strong platform for easy rotation, lifting, and stabilisation for efficient and safe handling.

Many lifting tables restrict movement to just one position. But ST-3/O/C comes with three-foot pedals, enabling operators to adjust its height from any desired side. This means:

Hence, it’s useful for positioning protective materials and wrapping sofa elements.

2. Swivel Tabletop for Full 360° Access

Due to its swivel tabletop covered with carpet, it can easily rotate and lock at each 90° with its spring brake system. We install special metal strips on the carpet to dissipate static electricity and make it easier to slide the sofa across the surface of the tabletop.

This enables packers to:

3. A Middle Positioning Beam Enables Easy Packing with Smooth Lift

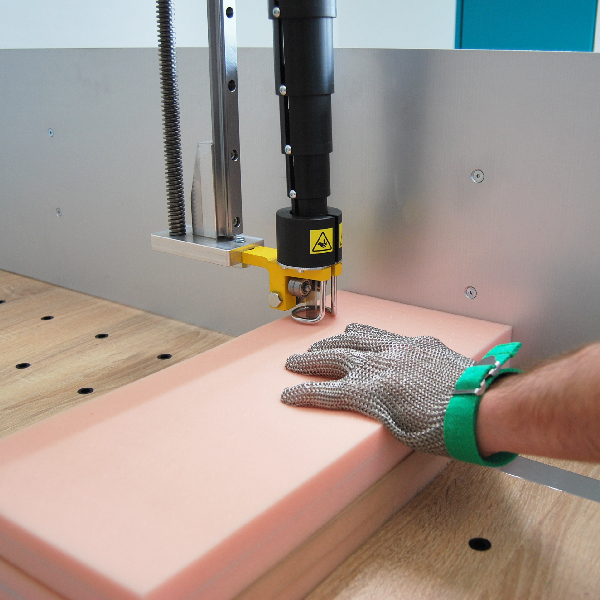

The lifting table comes integrated with a pneumatically controlled positioning beam. This particular element of the table enables the gentle raising of the sofa, just enough to attain clearance between the tabletop and the sofa. The downward movement of the beam is gravitational so it minimizes risk of limb crushing.

It enables the operator to:

Due to this small detail, there’s a significant reduction in physical labour while enhancing the packing precision.

4. Proven Energy Savings and Productivity Gains

Utilising this lifting table enables the following benefits:

This represents quantifiable, actual changes with direct implications on operational and productivity expenses.

The sofa packaging also involves precise cutting and unwinding of packaging foil and cardboard. That’s exactly when the K2-0597 Foil Unwinding and Cutting Table is required. It works effortlessly with the ST-3/O/C by enhancing its workflow accuracy and speed. Although one can use own solution to work with ST-3/O/C table instead of K2-0597 table.

1. Smooth, stable unwinding

Its structure consists of anodised aluminium that’s lightweight yet strong. The table also includes a roller clamp that holds foil or cardboard in place at the time of unwinding for controlled, clean feeding of material without any tangles.

2. The table can accommodate large rolls of material

It has a capacity for rolls up to:

As a result, it supports long production runs without consistent roll replacements.

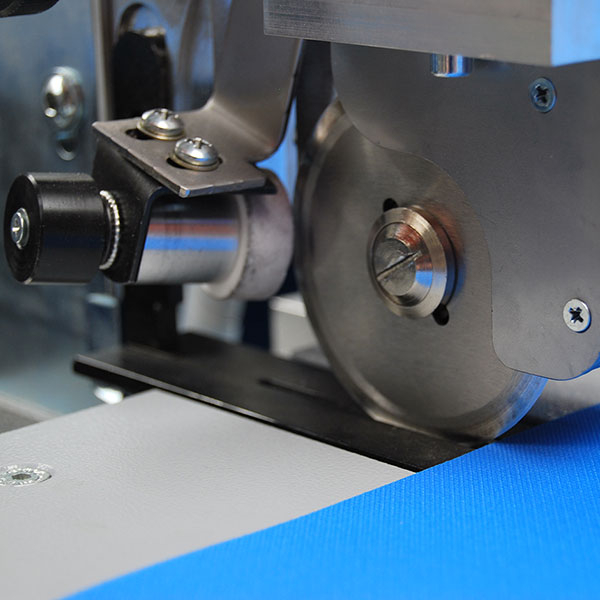

3. Integrated with a professional electric rotary knife

The K2-0597 comes integrated with the customized version of Great Ocean RSD-65 electric rotary knife to enables:

Due to this, the table helps in eliminating uneven tearing while speeding up the entire packing cycle. The knife can be operated manually for better user control.

Conclusion:

To improve the sofa packaging process, you not only have to focus on increasing speed but also on ergonomics, worker safety, consistency, and product protection. With the two specialised equipment, manufacturers at sofa facilities can upgrade their entire workflow with a modern, well-engineered solution.

For manufacturers seeking ways to optimise their production floor, investing in these machines is a practical decision. Visit Rexel Poland’s official website to know more about these devices in detail.

You Can Also Read: Improve Your Mattress Production with the SK-3 AIRSEW Sewing Table

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>