In the mattress production industry, ergonomics, precision, and efficiency are as vital as the quality of the end product. With increasingly complex and heavy materials being used in factories, it is essential to invest in the right equipment to make a difference. One such innovative piece of equipment is the SK-3 AIRSEW Mattress Cover Sewing Table with Air Cushion, which has been revolutionising mattress cover production.

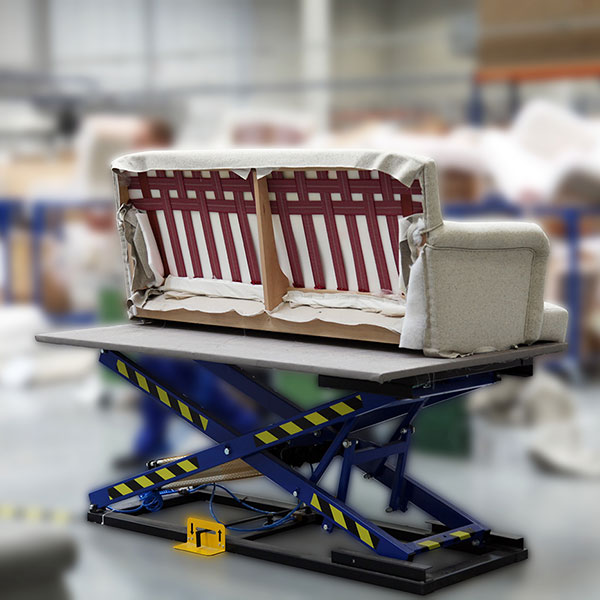

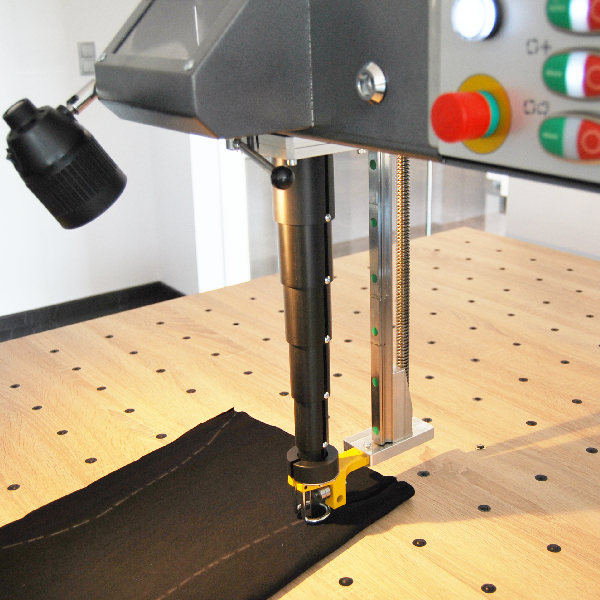

Air-blowing sewing tables are versatile machines for handling bulky or heavy fabrics. They can sew mattress covers, upholstery (chairs, sofas, car seats), industrial bags (sandbags, cable bags), banners, tents, tarpaulins, and outdoor gear like boat covers or padded mats. The air system lifts and smooths layers, making thick or multi-layered materials easier to stitch precisely.

Continue reading to explore how this specific table customises and optimises the workspace while being a valuable asset in today’s mattress production.

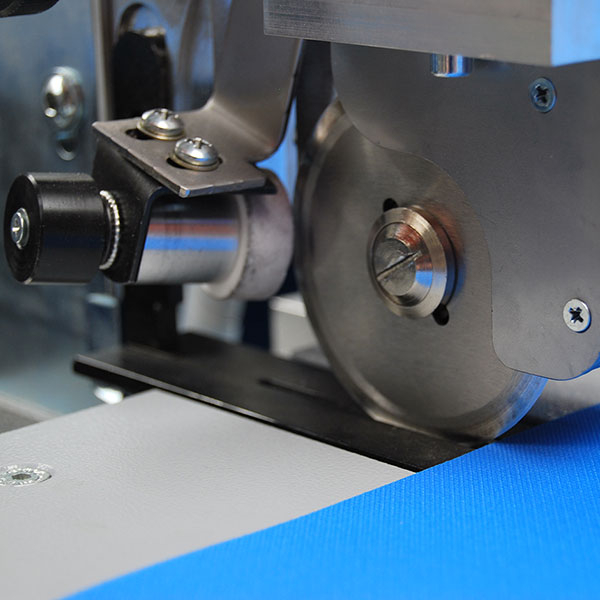

Durability is non-negotiable in modern industrial environments. The SK-3 AIRSEW sewing table consists of closed steel profiles for a robust frame to withstand heavy, consistent workflow. Another important thing is stability to handle large mattress cover production because even minor wobbling or vibrations can impact the sewing precision.

The 25 mm laminated MDF tabletop, finished with white PVC, provides a professional look while also being highly resistant to wear and tear. This means the table not only performs exceptionally but also maintains a clean, modern appearance in the factory setting.

Additionally, each tabletop connection is reinforced with supporting profiles underneath, adding to the overall strength and longevity of the workstation.

Also Read: Automated Pharmacy Dispensing Systems Revolutionising Healthcare

Since mattress covers are heavy, bulky, and complicated to maneuver, traditional sewing tables may cause friction while working. This makes it difficult to move covers across the surface smoothly. This is where you need the SK-3 AIRSEWair cushion system to make the task convenient.

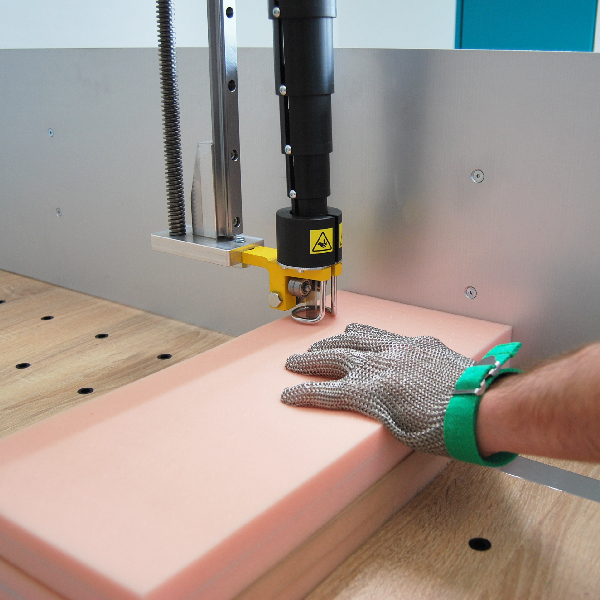

The advanced sewing table is the result of precisely engineered air holes to release controlled air streams. This helps in creating a near-frictionless surface for working. So, even the heaviest covers are easy to move and adjust with less effort. For workers, it means faster production, lesser fatigue, and better stitching accuracy.

Thanks to the variable air flow control in its system, operators can easily adjust its air blowing intensity based on the type of material. Whether you are sewing heavy-duty or lighter fabrics, the table adjusts effortlessly.

Operator comfort is one of the standout abilities of the SK-3 AIRSEW. This table is integrated with adjustable levelling to adjust height precisely to suit various production or workers’ setups. With the right height range from1025 mm (+75 mm, -225 mm), it offers better flexibility to reduce strain and provide flexibility during long shifts. Due to this customisation, an operator works comfortably to minimise workplace injuries and higher productivity.

Custom Sizing for Unique Needs

Since every matter factory is unique, its workflow, layout, and production needs are also distinct. Keeping this in mind, Rexel Poland’s SK-3 AIRSEW comes in custom sizes to ensure the table seamlessly fits into any workspace.

Due to its standard dimensions – 2400 mm in width and 4140 mm in length, it’s suitable for managing large mattress covers. We are able to customize dimensions as per the factory’s requirements offers flexibility for optimising the flow of production and space utilisation.

Here’s why to choose the SK-3 AIRSEW for your mattress production:

Today’s mattress production needs solutions that are forward-thinking and practical. When you incorporate the modern SK-3 AIRSEW Mattress Cover Sewing Table into your production unit, you not just boost efficiency but also curate a more sustainable and ergonomic working environment.

Whether you want to build a new production line or renovating your existing setup, tailoring your workspace with this modern sewing table ensures your factory is future ready for advanced textile manufacturing.

Conclusion

The modern SK-3 AIRSEW sewing table is a productivity tool for making mattress cover manufacturing faster, smoother, and highly efficient. With its advanced features and customizable options, it’s a major investment to improve both worker satisfaction and performance.

For modern mattress manufacturers looking for high-quality sewing and more efficiency, the SK-3 AIRSEW is a game-changer. Explore our website to find out more information in detail.

You Can Also Read: Guide to Aluminium Profile Cutting Machines PA-1 and PA-2

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>