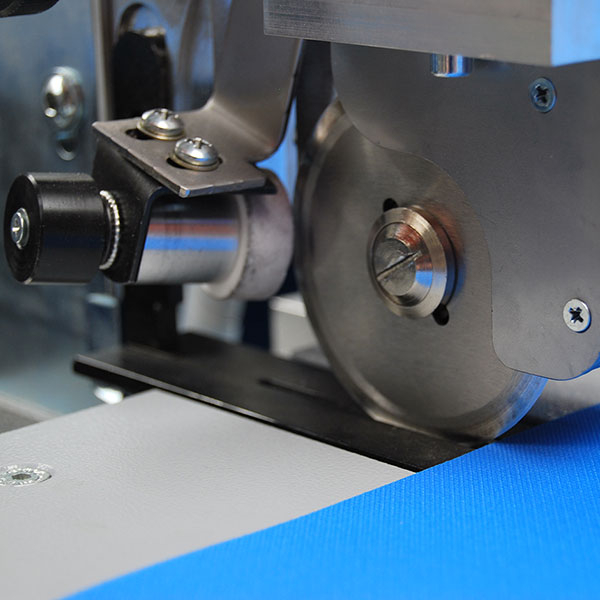

There is a wide range of textile rewinding machines on the market to choose from. Each machine comes with its own set of characteristics.

There is a wide range of textile rewinding machines on the market to choose from. Each machine comes with its own set of characteristics. Each machine is also ideal for doing a specific job. So, before settling for one option, there are various considerations to keep in mind. It is because there are several factors to consider for selecting the right rewinding machine for textiles.

Hence, keep in mind all the essential factors, we are this comprehensive quick guide to make your buying decision easier.

Well, a rewinding machine is ideal to perform rewinding options of slit roll reels with uneven edges or tension. These are perfect for rewinding films with laminating paper, paper rolls, or aluminum foil after slitting. These are available in diverse assortment sizes along with the capability to operate manually or automatically for high-volume tasks.

However, you need to remember that all machines are not the same. The machine to rewind foil has various components, such as an unwinder, an unwind table, a feed table, a control panel, a rewound roll, and a reel stand.

The packaging and textile business often makes the most of the textile rewinding machines. There are many factors to keep in mind before thinking of investing in this rewinding machine for a company. You need to purchase already wound rolls so that it’s much simpler for releasing the goods on the market, as rapidly as possible.

It would be simpler for storing the inventory if you buy rewound rolls after use. There are many pre-wound rolls out there. However, the price of those is generally higher. It is vital to find a role that may accommodate your needs if you have a small company and want to get a sizable order. As per the roll manufacturer, you may need to wind it again before use.

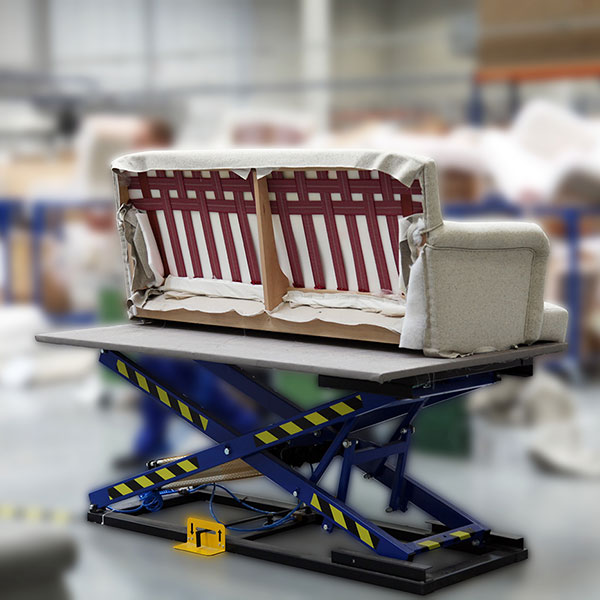

Also Read: Why Are Pneumatic Press Used In Upholstered Seat Assembly Line?

Here are the three main types of rewinding machines you need to consider buying:

Manual Rewinding Machine

A manual rewinding machine operates via hands. The most common application in their activities is of somewhat modest size with exceptionally high output volume. This machine is well-suited for single-person operation for small businesses or other settings that have restricted production requirements.

Semi-Automatic Rewinding Machine:

These are partially automated, hence called semi-automatic rewinding machines. It finds the common applications are of modest size with not-so-high volume output. This is also a good choice for single-person operations in small businesses.

Automatic Rewinding Machine:

It is a fully automated machine that’s essential for large-scale operations where production is enough for its use. The automatic rewinding equipment is ideal for large-scale activities handled by a group of individuals who work together.

Here are some major factors to consider when choosing a textile rewinding machine:

1. Type:

There are three major types of textile rewinding machines in the market. These are operated manually, semi-automatically, or automatically. You can choose the best one as per your requirement, ease of operation for you, and other essential factors. It is best to check the pros and cons of each machine type and then decide what to do.

2. Features:

Rewinding machines come integrated with different features that enable users to customize the device as per their needs. You may buy manual machines with semi-automated operation or complete automatic devices.

You may select various features of the desired device, like the spool size, the housing type, the material it is made of, etc. Everything depends on the type of machine you choose.

3. Operation Speed:

When buying a textile rewinding machine, carefully choose how rapidly it can perform specific tasks. If you operate a business with a higher production rate, you need to consider how rapidly a machine does it work.

If you are running a business with a higher production rate, you need to pay attention to how rapidly a device manufactures a roll. It is vital to compare the speeds of various machines before selecting one specific product.

4. Price:

The price of a rewinding machine is vital to consider. Before you make the final buying decision, you need to identify the right price range available for you. Hence, you can select the right equipment that may fall within your budget.

Conclusion

Want to buy a textile rewinding machine? It is vital to know there are various factors to consider. You have to determine each factor before settling for one choice. It may assist you in shortlisting the right equipment as per your industrial needs. At Rexel Poland, we offer the best quality rewinding machines for various applications. Explore the website to check out the available options.

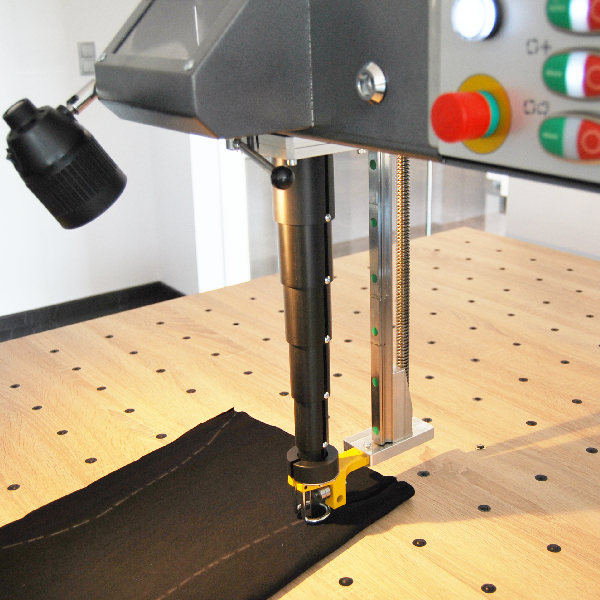

You can also read: How to choose a roller blinds cutting table for your production: a quick guide

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>