While enjoying the ergonomic design of office chairs and their backrests, have you ever thought about their manufacturing process?! Of course, none of us would have! But there is no harm in knowing that. Throughout the manufacturing process of upholstered seats, various tools are used, of which the pneumatic press for chair seat making is of great use. The press helps manufacturers fix the stitches and secure the fabric perfectly so that furniture last longs and maintains the quality as it was when new.

But what is the use of a pneumatic press while making upholstered or even beds?! To know the answer to this question, you must first know about the pneumatic press and its working principle.

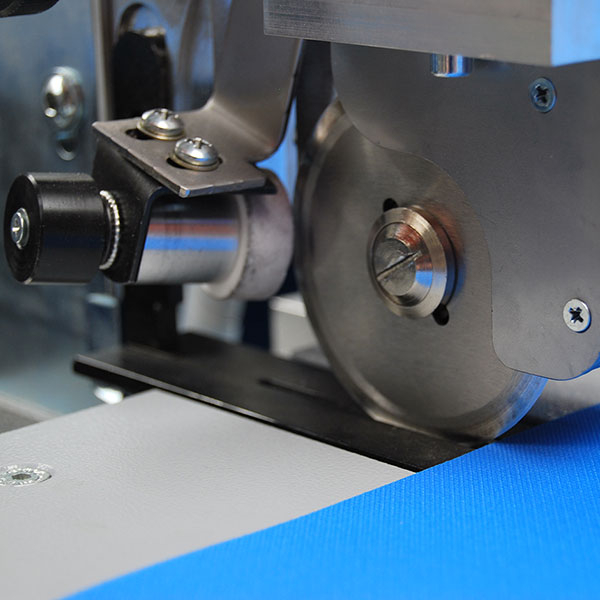

Pneumatic press is a heavy-duty machine that is used to deform work pieces during the manufacturing process. The press can perform multitudes of functions, including forming, drawing, bending, punching, and cutting workpieces as required in the manufacturing industry.

The pneumatic press generally is forming press that helps manipulate the workpiece by applying pressure. The machine typically has a rectangular frame that helps apply the pressure and complete the manufacturing process.

Pneumatic presses work with pressurized gas or air in action. Working with pneumatic presses is much easier than working with hydraulic presses because gas or air is easy to work with or maintain. Moreover, the pneumatic press;

Running a business in top-notch condition requires the availability of all types of tools and heavy-duty machinery to start with. You don't know when you have a huge order to deliver, and thus, your inventory should be all decked up with necessary tools and machinery. Of all, the pneumatic press for bed upholstery and upholstered chairs is of great importance; thus, you should invest well.

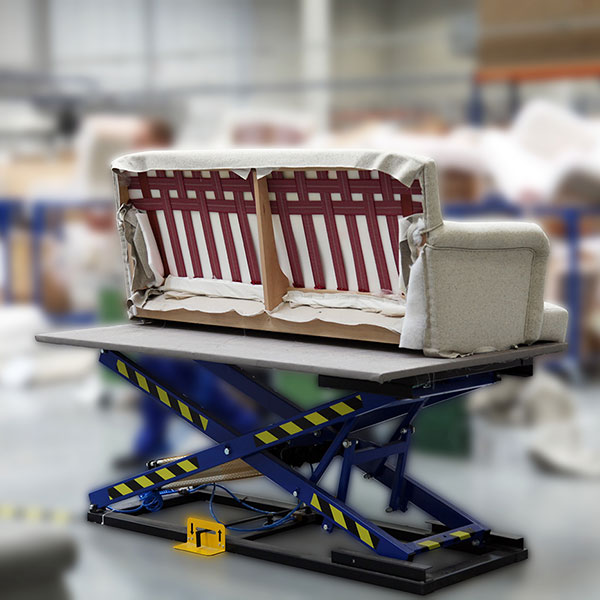

One such product in the market with a great name is Rexel Poland's PNEUMATIC PRESS FOR UPHOLSTERED SEATS PDP-1.

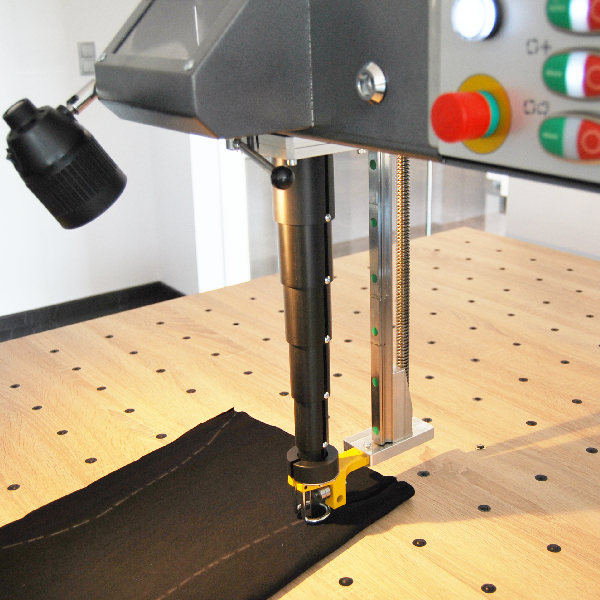

The press is a compact version for upholstering small elements in making an upholstered seat or bed. This PDP-1 model comes with the specifications mentioned below.

Good for office chair manufacturing

This compact machine version is perfect for manufacturers dealing with office chairs and bed upholstery production. The machine is compact and takes significantly less space in the workplace.

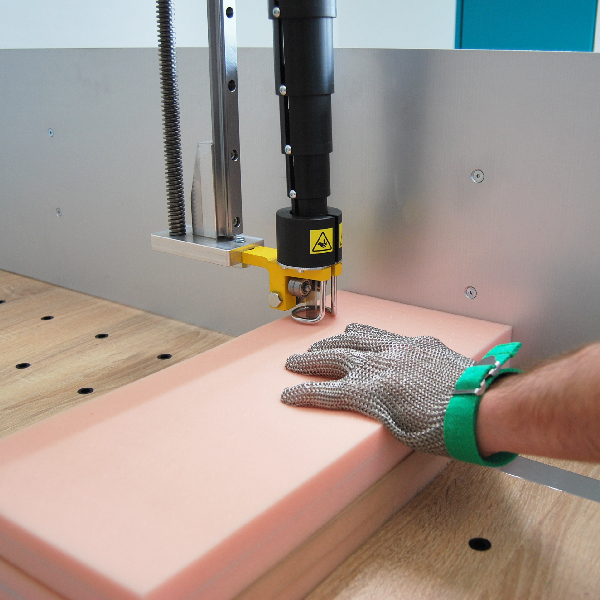

This pneumatic press from Rexel Poland comes with a two-button start system for workplace safety and precision. The two-start button ensures work safety while operating the machine.

The very important factor about this machine is that it allows comfortable work height per the operator's comfort. Moreover, the pneumatic cylinder comes with a long and lower stand (telescopic) so that operator can adjust it according to his comfort while working.

The machine ensures the right tension while working with chair seats, bed upholstery, and backrests. Whether the process involves working with fabric, foam, or chipboard, the machine provides the right work manipulation devoid of material.

The pneumatic press is an excellent choice for assembly lines and considerably huge businesses. It improves efficiency and productivity in the long run. Moreover, it ensures great ROI over the time of use.

If you are curious to know more about the pneumatic press and its specification, get in touch with the experts at the company. To streamline the process, fill out their 'Contact Us’ form and wait for one of their experts to address your needs.

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>