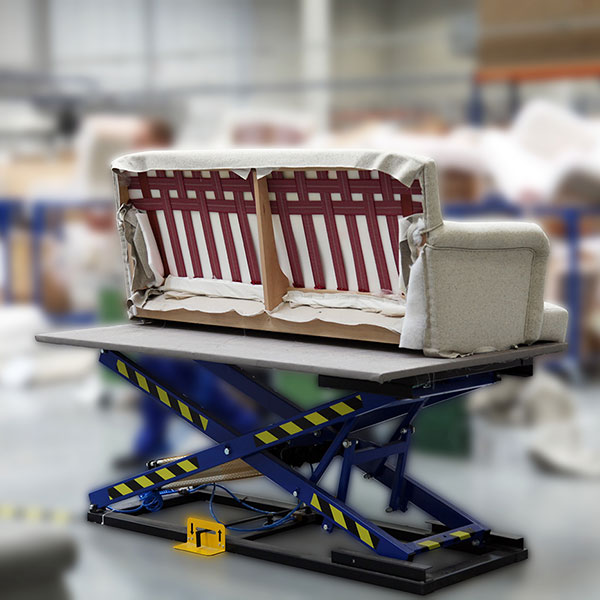

Looking for the right machine to make the manufacturing of roller blinds smooth and easy? If so, you need to choose the top quality machines for high performance. Control lift (Inspection hoist for blinds) is designed for testing of roller blinds. This control lift allows checking the levelness of slats in the blinds. Checking the blinds ensures that the fabric is properly wound on a tube and to make adjustments if necessary.

With efficient and proper inspection of roller blinds’ fabric, the manufacturing units can produce accurate sized blinds. It also helps with fast and secure placement of every system without further need for setup again and again. It means that a single system can regulate all different types of roller blinds without changing any parts.

Here are various features and advantages of premium roller blinds manufacturing machines:

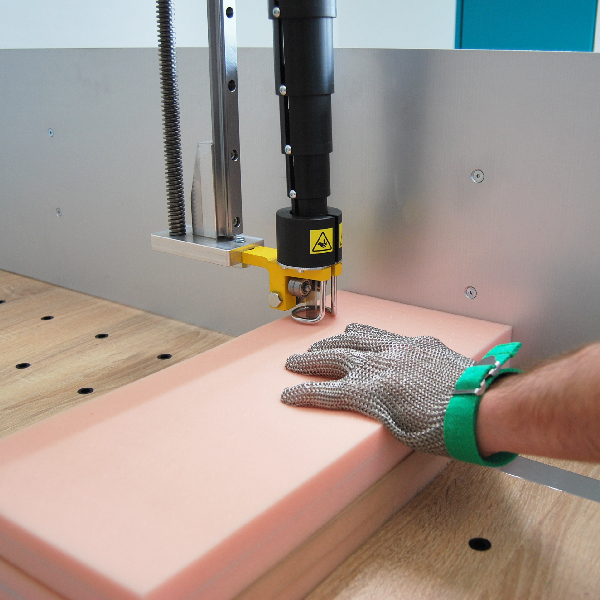

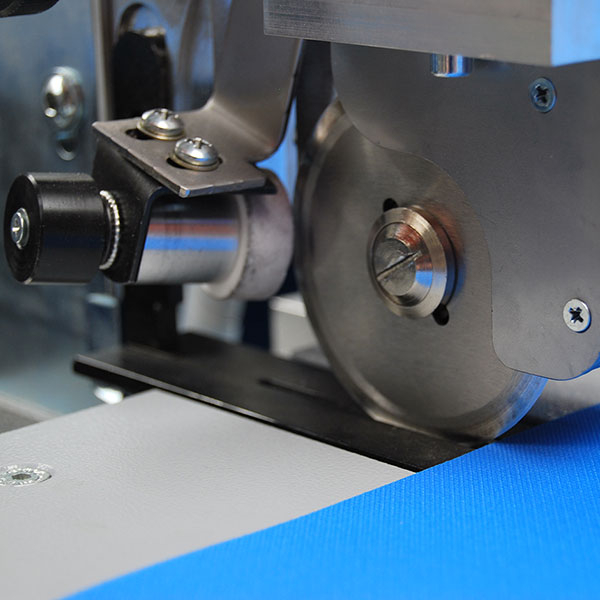

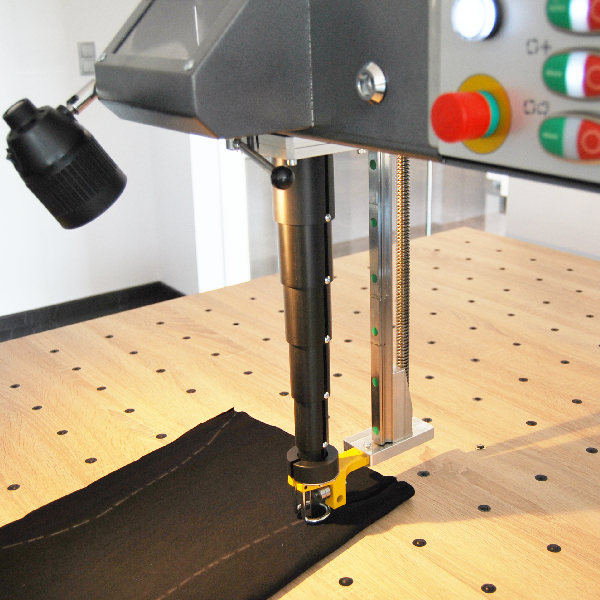

At Rexel, we provide distinct types of roller blind manufacturing machines. Our machines are divided in a few groups: cutting tables for roller blinds, inspection hoists, automatic positioners for aluminum cutting, material rewinding machines and some other special applications machines.

Also read: Selecting the Top-Notch Textile Rewinding Machines

In this article we will discuss the Roller blinds inspection hoists. REXEL company manufactures 3 types of inspection hoists: WK-1, WK-1/HD and WK-2/HD. To each hoists there is a set of holders.

Detailed description of different types of inspection hoists:

WK-1:

WK-1 control lift (inspection hoist for blinds) is suitable for testing roller blinds. It helps in keeping the check on the levelness of blind’s slats. Another reason for inspecting the blinds is to make sure that the cloth is wound accurately on the tube while making the necessary adjustments.

Since WK-1 is foot-controlled, it is easier to use for different kinds of holders with various types of blinds. Furthermore, its adjustable design option helps in creating various blind sizes with ease. And, thanks to its strong yet lightweight construction and lightweight, one can do inspections of blinds quickly with thorough efficiency. It can handle up to 20 kg of blinds total weight.

WK-1/HD (single post) inspection hoists help in inspection, as well as assembly of wooden blinds, Venetian blinds, and exterior shutters. Their machine frame consists of anodized aluminum and steel profiles along with height-adjustable pedals.

It also comes integrated with an inverter that helps in smooth start and stop. Besides that, it has an extra sliding brake to lock the horizontal bar if any technical issues arise. It can handle up to 30 kg of blinds total weight.

WK-2/HD (double post) inspection hoist is also great for inspecting and assembling wooden blinds, Venetian blinds, and exterior shutters. Rest is has all the same features as WK-1/HD. The only difference is that it is double post compared to the single post WK-1/HD. It can handle up to 50 kg of blinds total weight. You can choose anyone as per your manufacturing requirements.

--------------------------------------------------------------------------------------------

It is a complicated question to answer, particularly if you are seeking a new cutting table. But you must know that the more features, the higher will be the cost of a cutting table. One also needs to analyze the company’s requirements and also determine which machine is suitable. The cost-effectiveness, production potential, and required features are some factors to consider during the purchase.

If you still have more questions about the roller blinds manufacturing machines, contact the team of Rexel to find a suitable machine for your company. Need something more besides the roller blinds cutting machine? Explore our equipment page.

You can also read: How to choose a roller blinds cutting table for your production: a quick guide

Conclusion

Inspection hoist or control lift for blinds are a great equipment for testing roller blinds. It also helps in monitoring the slats’ levelness in blinds. This equipment is essential for roller blinds manufacturing for leveled slats and winding of roller blinds. The roller blinds manufacturing firms will be able to produce precise roller blinds with the help of inspection hoists. Looking for the best quality inspection hoists or control lift for blinds? But the best one in table in Poland at Rexel website.

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>