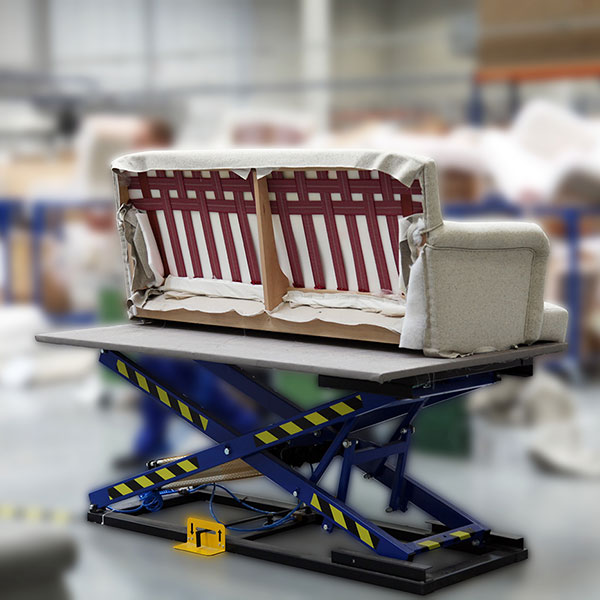

The pneumatic lifting table is a versatile piece of equipment used in many industries for a variety of functions. These tables are particularly useful in the furniture production industry for tasks like gluing and upholstery. The main function of the table is the capacity to lock the tabletop in 12 different locations by using the pneumatic blocking actuator with a foot lever. The table is built using the same framework as a typical ST-4 table.

Key Features

There is a solid steel profile along with a pneumatic cylinder to support the sturdy design of this table. The operator can conveniently change the height of the table as per their specific needs, using its foot-controlled pneumatic cylinder. The operator can even attach pneumatic tools to the table due to a connecting slot on the table. Swivel tabletop made of stainless steel is extremely easy to clean.

Also read: Sewing Machine Chairs – The Comfort Lies In Features

Given below are some notable benefits of using a pneumatic lifting table for efficient gluing:

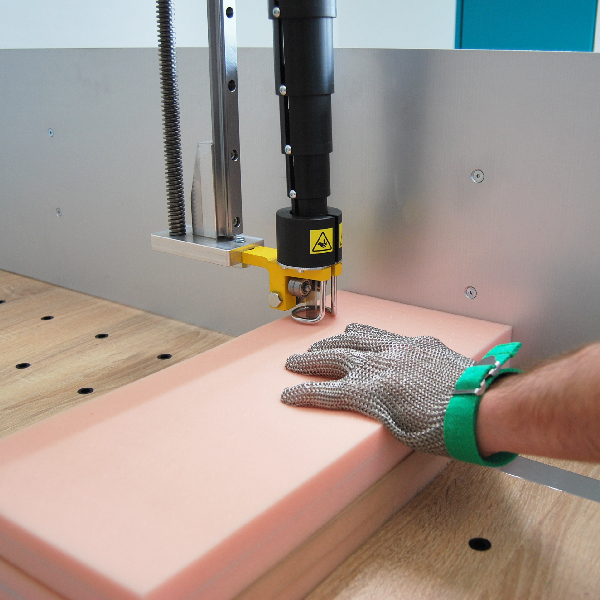

Increased Accuracy

A pneumatic lifting table for gluing helps users to work with accuracy and precision. This table comes integrated with a foot-controlled pneumatic cylinder that makes it easier to adjust the table’s height. This ensures one can accurately complete the gluing process.

Better Productivity

Due to the table’s ability to easily adjust its height, one can work on it more efficiently while minimizing the time for completing their tasks. Hence, it helps in improving their work productivity.

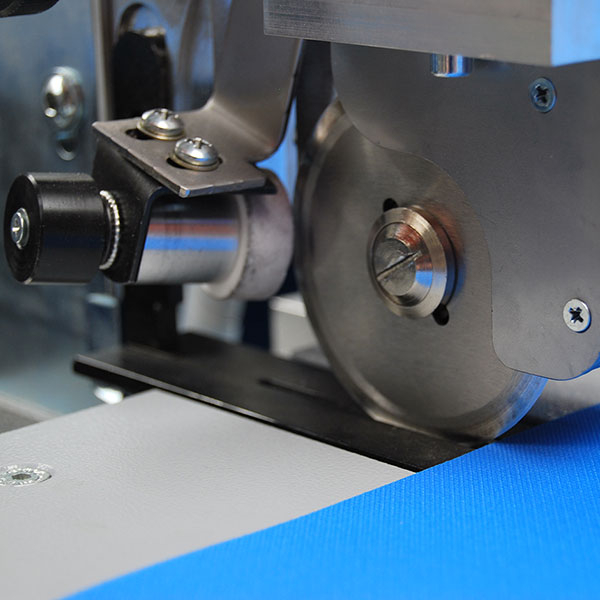

Enhanced Safety

The main advantage of using a pneumatic lifting table for gluing processes is that it allows the operator to apply glue on top of the table. This reduces the risk of glue getting on the operator's clothing or skin, which can be hazardous. Additionally, all pneumatics are enclosed, ensuring that glue in the spray does not go inside the table, preventing potential damage to the table's pneumatic components.

No Mess

One of the major advantages of this table is that it enables the users to apply glue on the top of the table. Since all the pneumatics are enclosed, the glue in spray form cannot get inside the table. So, you don’t have to worry about any mess while working.

Reduces Work-Related Injuries

Due to the height-adjusting ability of the pneumatic lifting table for gluing processes, it reduces the strain on the user’s shoulders and back. This minimizes the risks associated with work-related injuries while enhancing workers’ well-being and health.

Offers Better ROI

A pneumatic lifting table for gluing is a cost-effective tool, as it needs minimal maintenance. With proper care, it can last for many years while offering better ROI.

Specifications

The model for this particular table is ST-4/B, with a working pressure of 6 bar (87 PSI). The tabletop dimensions are 1200 mm x 750 mm (47.24" x 29.52"). The pneumatic cylinder is D125x200, with a minimum height of 500 mm (19.68") and a maximum height of 820 mm (32.28"). The maximum load for the table is 90 kg (198.4 lbs).

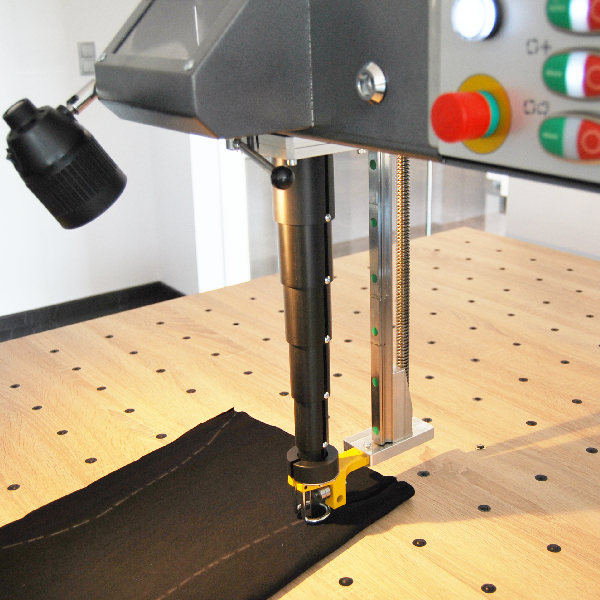

Thanks to the high versatility of the pneumatic lifting table for gluing process, it helps handle various tasks in distinct industries. Given below are some detailed applications of this table for efficient gluing procedures:

Upholstery:

In the upholstery industry, a pneumatic lifting table for the gluing process is essential. Since the table can lock in around 12 positions using the foot level, it is convenient to work with different upholstery tools. Plus, the connection slot on the table, helps different tools to easily connect to the table. This not only saves time but also improves work efficiency.

Woodworking:

The pneumatic lifting table is even beneficial in the woodworking industry. It helps the users to easily glue different parts of wooden objects to make a project successful. The table’s height-adjusting ability also makes it convenient to apply glue to various parts of a project. This helps the users to ensure everything gets glued up perfectly with precision.

Automotive Industry:

These tables are even useful for handling distinct installation and repair parts. It is possible thanks to the table’s connection slot for connecting various tools directly to the table. It helps in making it convenient for them for working on distinct parts of a vehicle.

Conclusion

The pneumatic lifting table is a powerful and flexible piece of equipment that can enhance output while using less energy. The table's strong construction and ability to lock the tabletop in 12 settings make it a handy asset to any furniture manufacturing business. Want to buy this pneumatic lifting table for gluing process? Explore Rexel Poland's website for it.

You can also read: Your Guide To The Best Ergonomic Industrial Sewing Machine Stand

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>