Efficiency and accuracy are two strong pillars of success in the modern textile industry. Whether it’s a small business or large-scale manufacturing, fabric handling requires reliability and precision for better product quality. Investing in Fabric Rewinding machines is important for companies to save time, streamline operations, and deliver high-quality products.

Rexel Poland understands the evolving need for advanced technology to meet the varying needs of the textile industry. The modern equipment, such as the P-4SE Fabric Rewinding Machine, adapts to the changing needs of textile production. This advanced machine is a revolutionary solution to enhance the fabric rewinding process.

When it comes to fabric rewinding, the process involves not just rolling the material from one spool to another. It needs experts for accurate length measurement, checking fabric quality, and preparing rolls for direct sale or further processing. Insufficient equipment can cause material wastage, errors, and downtime. Therefore, companies need high-performing machines to overcome such challenges with ease.

Thanks to fabric rewinding machinery, businesses attain:

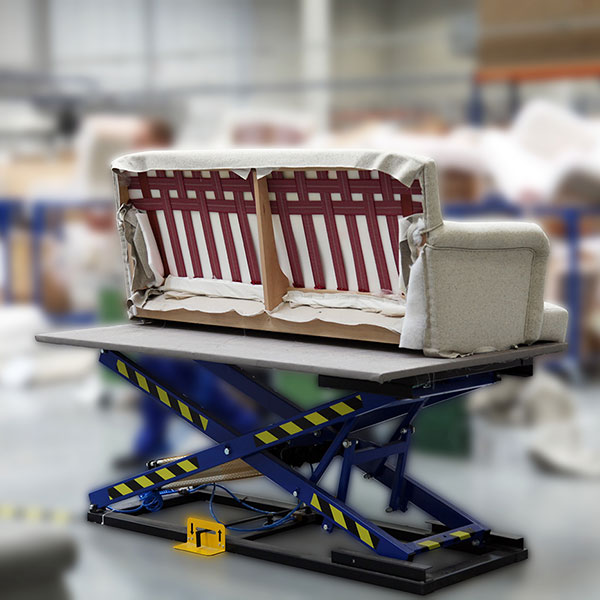

The P-3S model is a powerful winding device that has set a benchmark in fabric rewinding. This has an amazing ability to measure accurate fabric length. Plus, its ergonomic design makes it a reliable choice for global textile manufacturers.

Key features:

This machine is also available in multiple versions to meet different companies’ distinct needs:

These models enable businesses to increase their workplace efficiency, as well as flexibility.

However, with increasing industry demands, companies need solutions that improve productivity while maintaining reliability and safety. That’s when you need the advanced P-4SE.

Also Read: Improve Your Mattress Production with the SK-3 AIRSEW Sewing Table

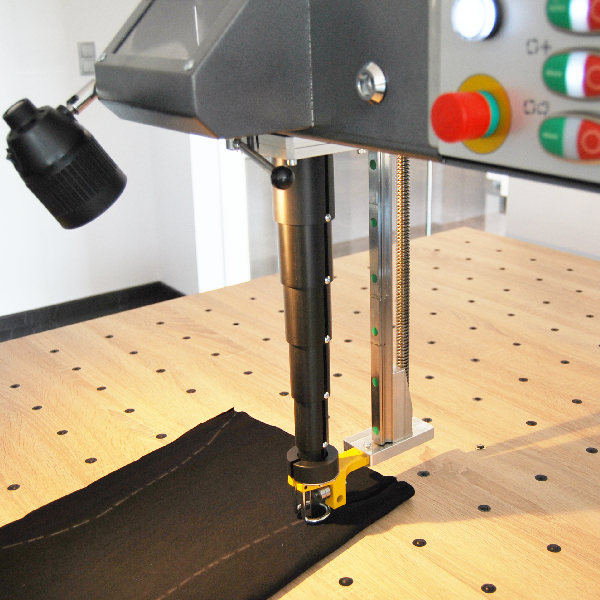

The P-4SE Fabric Rewinding Machine is integrated with next-generation features to offer better performance than the P-3S series. This modern machine is more automated and has better ergonomics for helping businesses modernize the way they handle fabrics.

Reasons to upgrade to the P-4SE:

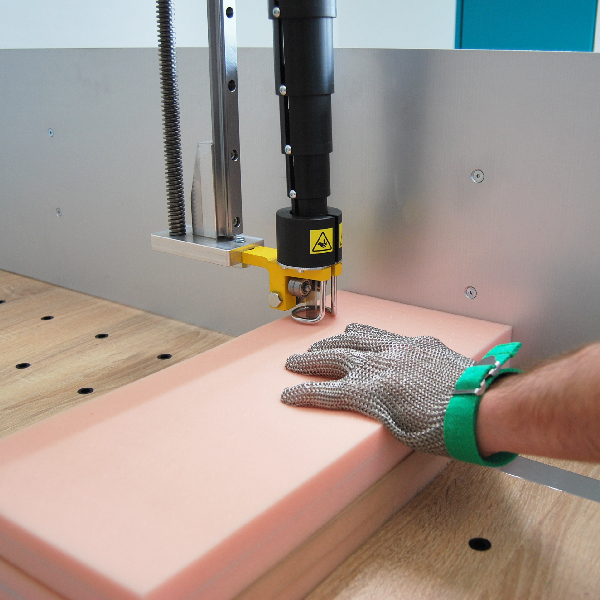

1. Advanced Length Measurement

The P-4SE is integrated with highly digital encoder compared to the P-3S that has a mechanical counter. The encoder is connected to the touchscreen panel and PLC that allows the machine stop when the desired length is reached.

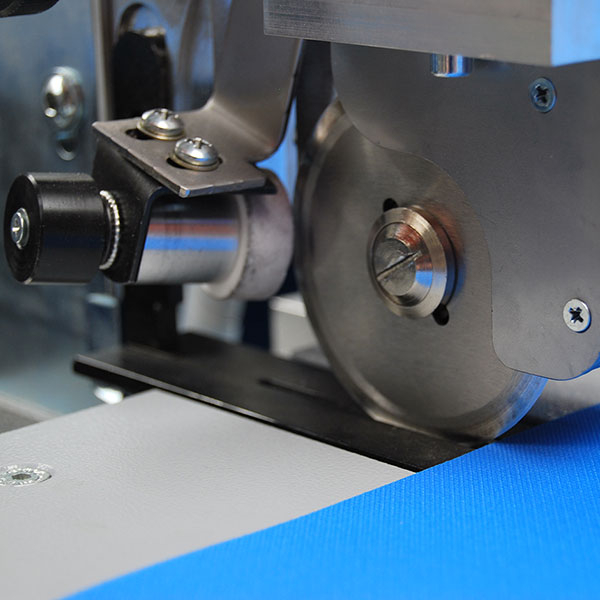

2. Better Winding Performance

The P-4SE can wind up the remaining material after the cut is made. This function is controlled by the speed controller.

3. User-friendly multilingual interface

Each machine we can program in your language. By default, the machine comes with Polish, English, Russian, German and Spanish. Other languages on request.

4. Modernized Safety Systems

Safety is a priority in any manufacturing facility. The advanced P-4SE is equipped with safeguards and emergency stop features to prevent accidents. Plus, its modernized electronics and improved relays ensure better protection.

5. Operator-Friendly Design

P-4SE boasts an operator-friendly design for convenient roll installation with better ergonomic controls. The waist-high feed cradle makes placing rolls in the cradle much more ergonomic.

6. Durable

Made from top-grade components and premium powder-coated steel, the P-4SE provides better durability than Rexel Poland machinery is renowned for. So, it is your long-term investment for consistent year-round performance.

Businesses attain the following benefits by investing in P-4SE:

P-4SE is ideal for:

P-4SE is adaptable to varying user requirements, whether you deal with industrial textiles, heavy upholstery materials, or lightweight fabrics. P-4SE works best for non-elastic, non-slippery materials only.

Conclusion

In today’s highly competitive textile sector, investing in modernized fabric rewinding machinery is of the utmost importance. Thanks to the P-4SE Fabric Rewinding Machine, Rexel Poland provides an advanced solution to businesses for delivering next-level automation and performance.

For businesses striving to enhance accuracy, efficiency, and workplace safety, P-4SE is the best option. So, leave behind the outdated machinery and embrace modern and smarter devices for fabric rewinding. Contact Rexel Poland today to learn more about this modern rewinding solution.

You Can Also Read: Automated Pharmacy Dispensing Systems Revolutionising Healthcare

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>