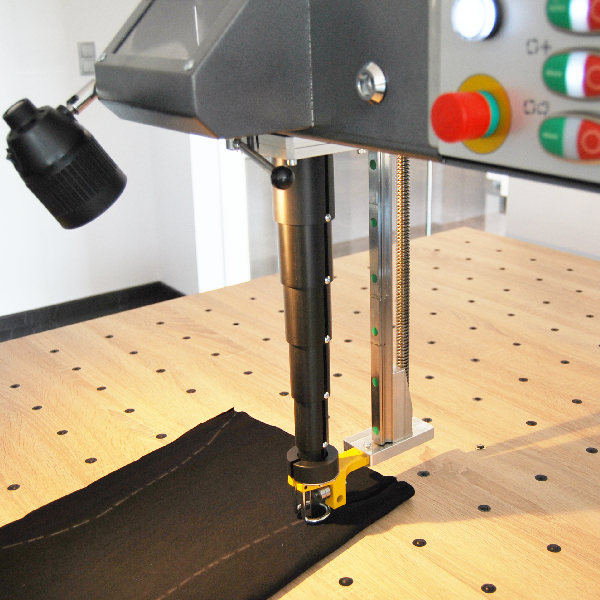

The automatic measuring stops are vital tools required in production lines and workshops to ensure accurate measurement before cutting materials. With these automated stops, there are fewer human errors. This results in more accurate cuts while making the production cycle much faster than manual effort.

PA-1 and PA-2 are ideal for handling materials, like metal, wood, and aluminum. Using these automated tools, one can attain accurate measurements while making the most of their convenient features for maximum efficiency.

It is an exact and versatile tool for length determination in industries that need accurate and faster cutting.

Key Features of the PA-1:

1. Precision and Accuracy:

It delivers better positioning accuracy up to 0.3 mm/m. This minimizes waste and improves material utilization.

2. Data Storage:

It can store data on its replaceable flash drive, enabling users to analyze production efficiency, track previous cuts, and optimize future cutting runs.

3. Touchscreen Interface:

It comes with an intuitive touchscreen panel for making the cutting process easy and simple. It comes in various languages, like English, Polish, Russian, and German. This way, it is easy to access by various operators across the globe.

4. Barcode Scanner Integration:

This feature helps to automate value input while decreasing the errors caused by manual data entry. This helps in faster workflow without any unwanted mistakes.

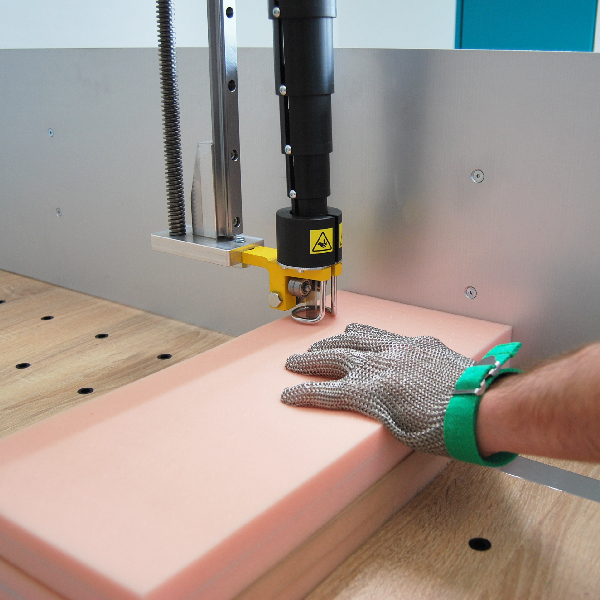

5. Pneumatic Clamps:

These optional pneumatic clamps are easy to control via a foot pedal. This ensures the materials are securely held without any extra manual effort.

Also Read: How to increase the efficiency of upholstered furniture production?

This particular tool is built upon PA-1’s features, enabling extra customization ability to boost versatility. It is perfect for industries seeking more specialized solutions while increasing workflow efficiency and productivity.

Key Features of the PA-2:

1. Roller Table:

It comes integrated with a tabletop with rollers to move materials conveniently during the cutting process. This enhances operational speed and efficiency.

2. Flexible for Various Applications:

It is flexible for different production setups and can be used without a saw for better control during measurement. It can also be integrated with custom tables for saws, as well as other machines for managing various production requirements.

3. Integrated Cutting Counter:

Its integrated cutting counter can track the number of cuts during the operation and signal the end of a series of several cuts. It helps monitor production procedures and during batch processing.

4. Improved Pneumatic Clamps and Barcode Scanning:

It comes with enhanced pneumatic clamps for better material holding for precise cuts. Plus, PA-2 supports a barcode scanner (optional) for input automation.

Comparison: PA-1 vs. PA-2:

| Feature | PA-1 Automatic Measuring Stop | PA-2 Automatic Measuring Stop |

|---|---|---|

| Precision | 0.3 mm/m | 0.3 mm/m |

| Touchscreen Interface | Yes | Yes |

| Data Storage | Replaceable flash drive | Replaceable flash drive |

| Barcode Scanner | Optional | Optional |

| Pneumatic Clamps | Optional (foot-controlled) | Optional (foot-controlled) |

| Roller Table | No | Yes |

| Cutting Counter | No | Yes |

Although both these measuring stops have similar core features, the PA-2 comes with additional equipment, like custom tables for saws. Plus, its roller table offers smother movement for better material handling. Besides that, PA-2 comes with a cutting counter feature for better batch production.

Applications of the PA-1 and PA-2:

Both are versatile for use in various industries, like:

1. Metalworking: These are ideal for cutting metal components, like aluminum tubs and profiles needed for manufacturing.

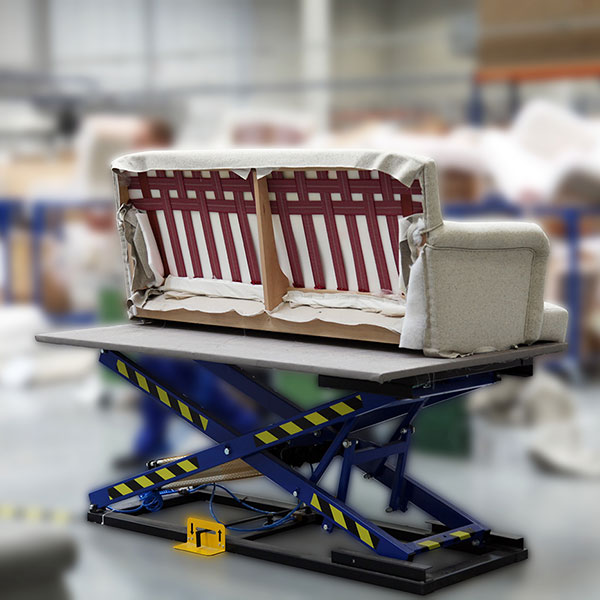

2. Woodworking: Useful for cutting accurate wood length for cabinetry, furniture, and construction projects.

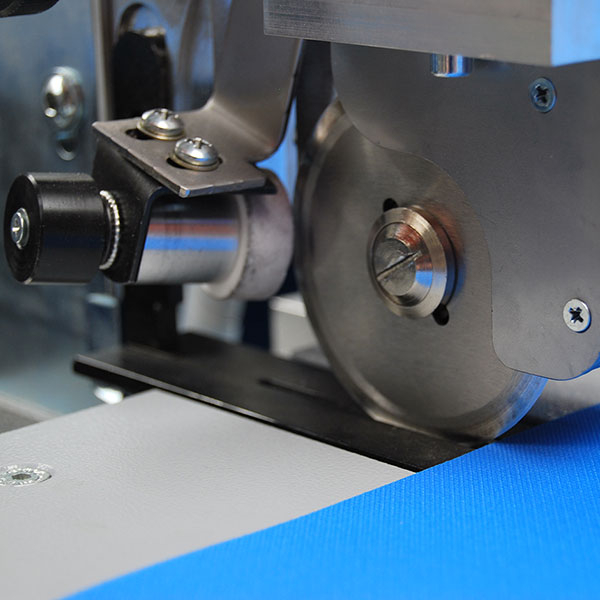

3. Textile Industry: Used to cut fabric with accurate measurements for large-scale production.

4. Automotive and Aerospace: These tools help in precise material cutting for manufacturing parts required in aerospace and automotive industries.

5. Packaging and Printing: Also, useful in highly accurate cutting of different packaging materials.

Conclusion

Rexel's PA-1 and PA-2 Automatic Measuring Stops are ideal tools for improving the efficiency and precision of cutting operations. No matter which tool you choose out of these, both reduce material wastage and enhance productivity.

By integrating these automated tools into your operations, it is easier to boost the quality and efficiency of distinct cutting tasks. Explore more on our website.

You Can Also Read: How Manual Measuring Devices PR-11 Enhance Your Work

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>