Roller blinds have gained immense popularity in recent years. They offer a stylish and functional window treatment solution for both residential and commercial spaces. Recognizing its popularity, are you thinking of starting your roller blinds business? But how to start a roller blinds business? In this article, we will guide you through the essential steps to kickstart your entrepreneurial journey. From assessing the local market to manufacturing and marketing, we'll cover everything you need to know to establish a successful roller blinds business.

1. Assess the Local Blinds Market:

Before diving into any business venture, it's crucial to evaluate the local market and determine if there is a demand for custom-made roller blinds and shades. Start by conducting thorough research in your target area. Identify potential customers, including homeowners, businesses, and interior designers, and understand their preferences and needs when it comes to window treatments. Additionally, analyze the competition to identify any gaps in the market that you can capitalize on, such as offering unique design options, personalized service, or competitive pricing.

2. Acquire Knowledge and Experience:

To excel in the roller blinds industry, it's important to gain as much knowledge and experience as possible. Seek out opportunities to work or intern at established blinds manufacturing companies. This hands-on experience will allow you to familiarize yourself with the production process, industry standards, and best practices. Additionally, consider attending workshops, seminars, or online courses specifically tailored to the blinds industry. These educational resources will help you refine your skills in areas like design, measurement, installation techniques, and customer service.

Also Read: Streamlined Roll Storage and Dispensing Solutions by Rexel

3. Look for Reliable Suppliers for Fabrics and Blinds Components:

Another important thing you need to consider while learning 'how to start a roller blinds business' is to establish good supplier relationships. Finding reliable suppliers for fabrics and blinds components is crucial for maintaining quality in your products. Look for reputable fabric suppliers who offer a wide range of options in terms of colors, patterns, and textures. This will ensure that you can cater to diverse customer preferences and provide a variety of choices. When selecting blinds components suppliers, prioritize those who provide durable and high-quality components. Remember, the longevity and functionality of your roller blinds will depend on the quality of the materials used.

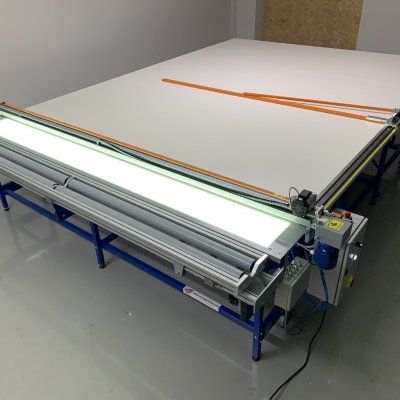

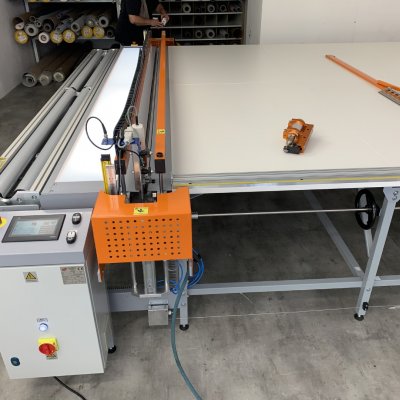

4. Explore REXEL Blinds Machines:

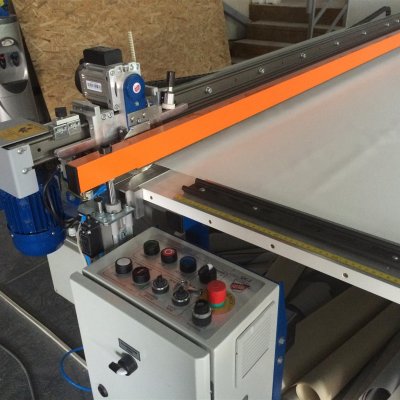

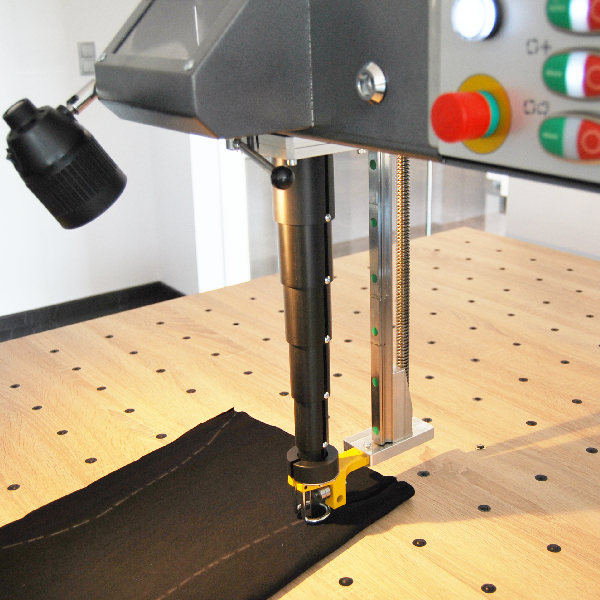

REXEL, a renowned manufacturer of blinds machines, offers cutting-edge equipment that can streamline your production process. Their roller blinds cutting tables, in particular, are designed to enhance precision and efficiency, enabling you to deliver impeccable products to your customers. When choosing a cutting table, consider factors such as the table size, cutting mechanism, and automation features. REXEL's website provides a quick guide on how to choose the right roller blinds cutting table for your production needs. Refer to this article to make an informed decision.

5. Invest in Machinery and Materials:

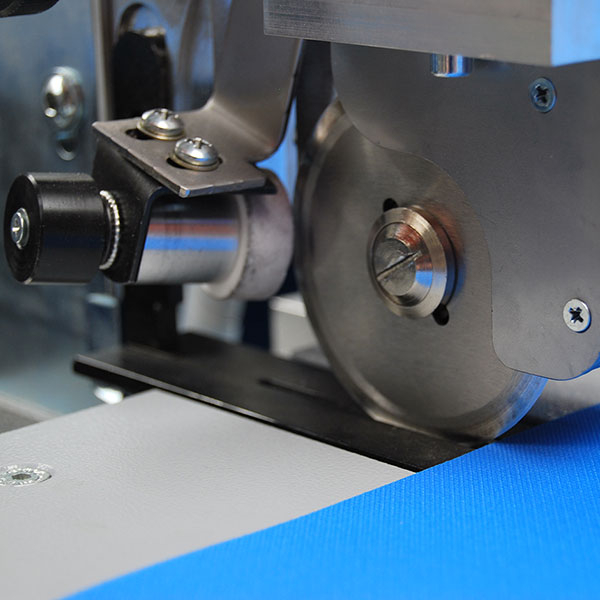

Once you've identified your suppliers and determined your production requirements, it's time to invest in the necessary machinery and materials. Purchase roller blinds manufacturing equipment that aligns with your production volume and quality standards. This may include cutting tables, hemming machines, fabric measuring devices, and other specialized tools. Ensure that your machinery is efficient, accurate, and durable to meet the demands of your growing business. In terms of materials, procure a variety of high-quality fabrics in different colors, patterns, and textures to offer a diverse range of choices to your customers.

In addition to manufacturing, establishing an online presence through a well-designed website is essential in today's digital age. Your website should showcase your products, provide information about your services, and offer a user-friendly browsing experience. Implement effective search engine optimization strategies to increase your online visibility, and consider integrating an online ordering system to simplify the purchasing process for your customers.

6. Make the Blinds:

After you have set up your production space, acquired the necessary machinery, and sourced high-quality materials, it's time to start manufacturing your roller blinds. Here are the key steps involved in making the blinds:

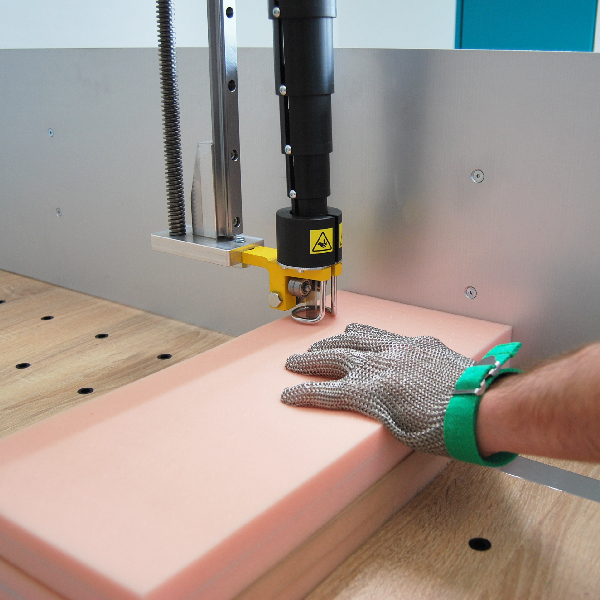

a. Measurement and Cutting: Begin by accurately measuring the windows for which the roller blinds are intended. Use precise measurement techniques to ensure a perfect fit. Refer to industry standards and guidelines to determine the appropriate measurements for different window sizes and styles.

b. Hemming and Seaming: Hemming is an essential step in roller blind production to prevent fraying and provide a neat appearance. Additionally, if you are creating wider blinds, you may need to seam multiple pieces of fabric together. Ensure that the seams are secure and inconspicuous, maintaining the overall aesthetic appeal of the blinds.

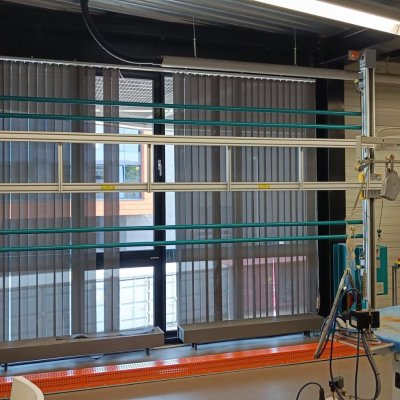

c. Mounting and Assembly: The mounting mechanism is a critical component of roller blinds. Follow the manufacturer's instructions and guidelines to assemble the necessary hardware, including the roller tube, brackets, and control mechanism.

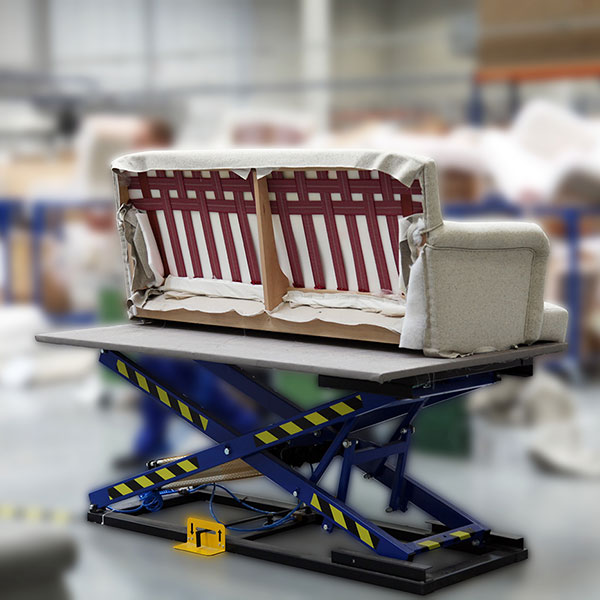

d. Finishing Touches: Before packaging the blinds for delivery or installation, conduct a thorough quality check. Inspect each blind for any defects, such as loose threads, uneven stitching, or misaligned components. One can use a roller blinds inspection lift to do this. Make any necessary adjustments or repairs to ensure that the blinds meet your quality standards.

Conclusion:

With a comprehensive understanding of how to start a roller blinds business, you can implement the right steps while beginning your new business journey. From assessing the local market and acquiring knowledge to sourcing materials and investing in machinery, each step plays a crucial role in establishing a successful venture. By following the guidelines provided in this article and staying committed to delivering high-quality products and exceptional customer service, you can create a thriving roller blinds business that caters to the needs and preferences of your target market.

You Can Also Read: Pneumatic Lifting Table for Efficient Gluing Process

REXEL Sp. z o.o.

ul. Radziwoja 11,

61-057 Poznań, Polska

SĄD REJONOWY POZNAŃ - NOWE MIASTO I WILDA W POZNANIU, VIII WYDZIAŁ GOSPODARCZY KRAJOWEGO REJESTRU SĄDOWEGO

Numer rejestru KRS 0001140682,

NIP 7822075401, REGON 631267170,

Wysokość kapitału zakładowego: 250 000 PLN

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>